VIP member

Synchronous Thermal Analyzer STA 449 F1 Jupiter

Synchronous Thermal Analyzer STA 449 F1 Jupiter

Product details

STA 449 F1 Jupiter®It is the world's most advanced synchronous TG-DSC analytical instrument newly launched by Nike, with unlimited configuration flexibility and unparalleled excellent performance.

• Covering a wide temperature range of -150 to 2000 ° C.

• Can quickly and deeply characterize the thermal stability, decomposition behavior, component analysis, phase transition, melting process, etc. of materials.

Easy to use top mounted style system with extremely high weighing system resolution (25ng resolution, weighing range 5g) and the highest long-term stability.

The freely replaceable DSC sensor has the highest sensitivity and best repeatability, used for measuring reaction/transition temperature and enthalpy, as well as specific heat.

A large number of optional enhancement accessories to meet the diverse and extensive needs of customers.

• Can be equipped with multiple furnace bodies with different temperature ranges and performance indicators, which can be switched by users themselves. (For a dual furnace structure, a rotating dual lifting device can be installed as an option)

• Pluggable sample holder (TG, TG-DSC, TG-DTA, etc.)

Automatic Sample Injector (ASC) capable of loading up to 20 samples simultaneously

• Automatic Vacuum and Filling Device (Autovac)

Provide a large number of accessories to choose from, such as sample crucibles with various materials, shapes, and sizes to choose from.

STA's unique temperature modulation DSC (TM-DSC)

Provide additional interfaces to connect with MS and FTIR for even more complex analysis.

• Covering a wide temperature range of -150 to 2000 ° C.

• Can quickly and deeply characterize the thermal stability, decomposition behavior, component analysis, phase transition, melting process, etc. of materials.

Easy to use top mounted style system with extremely high weighing system resolution (25ng resolution, weighing range 5g) and the highest long-term stability.

The freely replaceable DSC sensor has the highest sensitivity and best repeatability, used for measuring reaction/transition temperature and enthalpy, as well as specific heat.

A large number of optional enhancement accessories to meet the diverse and extensive needs of customers.

• Can be equipped with multiple furnace bodies with different temperature ranges and performance indicators, which can be switched by users themselves. (For a dual furnace structure, a rotating dual lifting device can be installed as an option)

• Pluggable sample holder (TG, TG-DSC, TG-DTA, etc.)

Automatic Sample Injector (ASC) capable of loading up to 20 samples simultaneously

• Automatic Vacuum and Filling Device (Autovac)

Provide a large number of accessories to choose from, such as sample crucibles with various materials, shapes, and sizes to choose from.

STA's unique temperature modulation DSC (TM-DSC)

Provide additional interfaces to connect with MS and FTIR for even more complex analysis.

Nike STA 449 F1 Jupiter®It can simultaneously test thermal effects (transition temperature, enthalpy) and changes in mass, with excellent stability, resolution, and accuracy. By selecting a suitable furnace body, installing high-performance sensors, and matching them with the most appropriate accessories, a synchronous thermal analyzer with top mounted samples can almost meet all applications. It combines high-performance thermal flow DSC with the world's most advanced nanogram scale balance, ensuring high sensitivity and resolution for DSC testing, as well as high resolution, low noise, and drift stability for TG testing.

STA 449 F1 Jupiter®By integrating the world's most advanced TG and DSC systems, its high-temperature DSC can test the specific heat of samples in the ultra-high temperature range. The temperature range of the entire system is -150 ° C... 2000 ° C (depending on the specific furnace body and sensor configuration). The dual furnace lifting device and automatic sampler (ASC) greatly improve the sample processing capacity, and ASC can automatically conduct testing at night or on weekends. Various DSC sensors provide true DSC testing over a wide temperature range (-150 ° C... 1750 ° C), accurately measuring small phase transitions and specific heat values.

The vacuum sealed design and high-resolution, metal encapsulated mass flow controller make the entire system an ideal tool for TG and DSC testing in research and industrial fields.

This fully equipped thermal analysis system can easily analyze trace amounts of active new drugs, trace impurities on semiconductor waveform converters, electronic components, medical transplants, and deviations in inorganic mixture components. Use our STA 449 F1 Jupiter®You will have an extraordinary feeling.

For gas emission analysis, STA can be combined with QMS or FTIR, or both simultaneously. Even with an automatic sampler, all tests can be conducted synchronously.

STA 449 F1 Jupiter®-Technical parameters

• Temperature range:- 150 ... 2000°C

Heating and cooling rate: 0.001 50 K/min (depending on furnace configuration; maximum linear heating rate of high-speed heating furnace is 1000 K/min)

• Weighing range: 5000 mg

TG resolution: 0.025 μ g

DSC resolution:< 1 μ W (depending on the equipped sensor)

• Atmosphere: Inert, Oxidation, Reduction, Static, Dynamic, Vacuum

Integrated quality flow meter with 2 purge gases and 1 protective gas

High vacuum structure design, with a vacuum degree of up to 10-4 mbar (10-2 pa)

For a single TG bracket, c-DTA can be equipped®(Computational DTA) function, used for temperature correction and additional DTA information acquisition.

TG-DSC and TG-DTA sample scaffolds are used for true synchronous measurement.

Automatic Sample Injector (ASC), capable of loading up to 20 samples simultaneously (optional)

• Combined with FTIR, MS, and GC-MS through a heatable adapter (optional)

• Unique Pulse TA extension function (optional)

STA 449 F1 Jupiter®-Software functions

STA 449 F1 Jupiter®The analysis and operation software is based on MS®Windows®XP and Vista®Proteus of the system®The software package includes all necessary measurement and data analysis functions. This software package has an extremely user-friendly interface, including easy to understand menu operations and automated workflows, and is suitable for various complex analyses. Proteus software can be installed on the control computer of the instrument for online operation, or installed on other computers for offline use.

DSC/DTA partial analysis function:

Peak annotation: It can determine the starting point, peak value, inflection point, and ending point temperature, and can perform automatic peak search.

• Peak area/enthalpy calculation: Multiple types of baselines can be selected for partial area analysis. You can choose the current mass at which temperature to use as the benchmark for enthalpy calculation.

Comprehensive analysis of peaks: Various information such as temperature, area, peak height, and peak width can be obtained simultaneously in one annotation.

Comprehensive glass transition analysis.

• Automatic baseline deduction.

• Crystallinity calculation.

• Oxidation induction period (O.I.T.) analysis.

• Specific heat analysis (optional).

• BeFlat®Function: Used for optimizing DSC baseline (optional).

DSC peak shape correction function: corrects the peak shape of the absorption/release peaks, incorporating the thermal resistance and time constant factors of the system into the calculation (optional).

TM-DSC (optional).

Peak annotation: It can determine the starting point, peak value, inflection point, and ending point temperature, and can perform automatic peak search.

• Peak area/enthalpy calculation: Multiple types of baselines can be selected for partial area analysis. You can choose the current mass at which temperature to use as the benchmark for enthalpy calculation.

Comprehensive analysis of peaks: Various information such as temperature, area, peak height, and peak width can be obtained simultaneously in one annotation.

Comprehensive glass transition analysis.

• Automatic baseline deduction.

• Crystallinity calculation.

• Oxidation induction period (O.I.T.) analysis.

• Specific heat analysis (optional).

• BeFlat®Function: Used for optimizing DSC baseline (optional).

DSC peak shape correction function: corrects the peak shape of the absorption/release peaks, incorporating the thermal resistance and time constant factors of the system into the calculation (optional).

TM-DSC (optional).

TG analysis function:

Manual or automatic labeling of weightlessness steps, in units of% or mg.

• Quality time/temperature labeling.

• Residual quality labeling.

The extrapolation starting and ending points of the weightlessness step can be marked.

• First order differentiation (DTG) and second-order differentiation can be applied to the thermogravimetric curve, and peak temperature labeling can be performed.

Automatic baseline and buoyancy effect correction.

• c-DTA®(Computational DTA): Can annotate the characteristic temperature and peak area of thermal effects (optional)

Manual or automatic labeling of weightlessness steps, in units of% or mg.

• Quality time/temperature labeling.

• Residual quality labeling.

The extrapolation starting and ending points of the weightlessness step can be marked.

• First order differentiation (DTG) and second-order differentiation can be applied to the thermogravimetric curve, and peak temperature labeling can be performed.

Automatic baseline and buoyancy effect correction.

• c-DTA®(Computational DTA): Can annotate the characteristic temperature and peak area of thermal effects (optional)

STA 449 F1 Jupiter®-Application examples

Water evaporation in Al2O3- excellent stability

Heating the alumina powder to 400 ° C (initial mass of 120.0mg) resulted in a weight loss of 16.50mg, mainly due to the evaporation of water, corresponding to the endothermic peak on the DSC curve. During the 50 hour constant temperature process, the mass change was only 11 micrograms, demonstrating excellent stability of the balance system.

Water evaporation in Al2O3- excellent stability

Heating the alumina powder to 400 ° C (initial mass of 120.0mg) resulted in a weight loss of 16.50mg, mainly due to the evaporation of water, corresponding to the endothermic peak on the DSC curve. During the 50 hour constant temperature process, the mass change was only 11 micrograms, demonstrating excellent stability of the balance system.

Reduction of Manganese Oxide

Manganese oxide (MnO2) is commonly used as an oxidant in the chemical field and as a cathode material in the battery industry. In the following STA measurement spectrum, there are two weight loss steps at approximately 600 ° C and 950 ° C, which are due to the reduction of MnO2 to Mn2O3 and ultimately to Mn3O4. The corresponding weight loss of 9.20% and 3.07% are in good agreement with the theoretical values, reflecting the high accuracy of the weighing system. On the DSC curve, there are two endothermic peaks corresponding to enthalpy of 432 J/g and 180 J/g, respectively. The DSC endothermic peak at 1200 ° C is a reversible structural transformation without corresponding weight loss process. The corresponding reversal during the cooling process (dotted line) corresponds to the exothermic peak at 1148 ° C.

Manganese oxide (MnO2) is commonly used as an oxidant in the chemical field and as a cathode material in the battery industry. In the following STA measurement spectrum, there are two weight loss steps at approximately 600 ° C and 950 ° C, which are due to the reduction of MnO2 to Mn2O3 and ultimately to Mn3O4. The corresponding weight loss of 9.20% and 3.07% are in good agreement with the theoretical values, reflecting the high accuracy of the weighing system. On the DSC curve, there are two endothermic peaks corresponding to enthalpy of 432 J/g and 180 J/g, respectively. The DSC endothermic peak at 1200 ° C is a reversible structural transformation without corresponding weight loss process. The corresponding reversal during the cooling process (dotted line) corresponds to the exothermic peak at 1148 ° C.

Decomposition of basic ferric sulfate

Basic iron sulfate (Fe (OH) SO4) is the basic raw material for synthesizing iron oxide and can be used as a pigment or magnetic storage medium. The commonly referred to ferromagnetic fluid contains superparamagnetic iron oxide nanoparticles, which can serve as contrast agents for magnetic resonance imaging. When the temperature is below 600 ° C, according to the results of STA-MS combined testing, there are two steps of dehydration process, corresponding to the peak with a mass number of 18 on the mass spectrum curve. Between 600 ° C and 800 ° C, SO2 and O2 are generated, corresponding to peaks with mass numbers of 64 and 32. The final product is Fe2O3 (hematite).

Basic iron sulfate (Fe (OH) SO4) is the basic raw material for synthesizing iron oxide and can be used as a pigment or magnetic storage medium. The commonly referred to ferromagnetic fluid contains superparamagnetic iron oxide nanoparticles, which can serve as contrast agents for magnetic resonance imaging. When the temperature is below 600 ° C, according to the results of STA-MS combined testing, there are two steps of dehydration process, corresponding to the peak with a mass number of 18 on the mass spectrum curve. Between 600 ° C and 800 ° C, SO2 and O2 are generated, corresponding to peaks with mass numbers of 64 and 32. The final product is Fe2O3 (hematite).

Building materials: phase transition of gypsum and quartz sand mixture

Gypsum and quartz sand are often used in gypsum and plaster. In this example, the gypsum dihydrate CaSO4 * 2H2O component in the sample undergoes a two-step dehydration process before 200 ° C, and finally transforms into anhydrous gypsum CaSO4 through the hemihydrate CaSO4 * 1/2H2O, with a total endothermic enthalpy of 122 J/g. Quantitative analysis shows that the sample contains 23.4% gypsum dihydrate. Anhydrous gypsum releases 18.3 J/g of heat between approximately 300 ° C and 450 ° C, forming β - CaSO4. The endothermic effect at an initial temperature of 573 ° C is due to the α →β phase transition in the structure of quartz (crystalline SiO2).

Gypsum and quartz sand are often used in gypsum and plaster. In this example, the gypsum dihydrate CaSO4 * 2H2O component in the sample undergoes a two-step dehydration process before 200 ° C, and finally transforms into anhydrous gypsum CaSO4 through the hemihydrate CaSO4 * 1/2H2O, with a total endothermic enthalpy of 122 J/g. Quantitative analysis shows that the sample contains 23.4% gypsum dihydrate. Anhydrous gypsum releases 18.3 J/g of heat between approximately 300 ° C and 450 ° C, forming β - CaSO4. The endothermic effect at an initial temperature of 573 ° C is due to the α →β phase transition in the structure of quartz (crystalline SiO2).

Phase diagram of alloys

Pt0.89Au0.1OIr0.01 is a dental alloy commonly used for inlays, crowns, and bridges. Dental alloys must have strength, formability, corrosion resistance, and biocompatibility. The test results show that during the heating process, there is an endothermic phenomenon on the DSC curve (solid line) at the extrapolated starting temperature of 1659 ° C, mainly due to the melting process, with a enthalpy value of 88J/g. During the cooling process, the DSC curve (dashed line) shows an exothermic peak (peak temperature 1684 ° C) at the starting temperature of 1685 ° C, mainly due to the crystallization process of the alloy, with a enthalpy value of -87J/g. At the highest temperature, there is a weight loss of 0.05%, mainly due to the onset of volatilization.

Pt0.89Au0.1OIr0.01 is a dental alloy commonly used for inlays, crowns, and bridges. Dental alloys must have strength, formability, corrosion resistance, and biocompatibility. The test results show that during the heating process, there is an endothermic phenomenon on the DSC curve (solid line) at the extrapolated starting temperature of 1659 ° C, mainly due to the melting process, with a enthalpy value of 88J/g. During the cooling process, the DSC curve (dashed line) shows an exothermic peak (peak temperature 1684 ° C) at the starting temperature of 1685 ° C, mainly due to the crystallization process of the alloy, with a enthalpy value of -87J/g. At the highest temperature, there is a weight loss of 0.05%, mainly due to the onset of volatilization.

Plastic

Plastic bottles, textile fibers, and films (such as packaging food) are the most common applications of high polymer PET (polyethylene terephthalate). The STA test results show that under N2 atmosphere, there is a step in the DSC curve before 100 ° C, mainly due to glass transition, and an increase in specific heat of 0.35 J/(g * K). The endothermic peak at 81 ° C is mainly due to relaxation phenomenon. The exothermic peak at 131 ° C is mainly due to the cold crystallization process. The endothermic peak at 255 ° C is the melting process. After 360 ° C, the sample began to decompose, accompanied by a 79.5% weight loss.

Plastic bottles, textile fibers, and films (such as packaging food) are the most common applications of high polymer PET (polyethylene terephthalate). The STA test results show that under N2 atmosphere, there is a step in the DSC curve before 100 ° C, mainly due to glass transition, and an increase in specific heat of 0.35 J/(g * K). The endothermic peak at 81 ° C is mainly due to relaxation phenomenon. The exothermic peak at 131 ° C is mainly due to the cold crystallization process. The endothermic peak at 255 ° C is the melting process. After 360 ° C, the sample began to decompose, accompanied by a 79.5% weight loss.

STA 449 F1 Jupiter®-Related attachments

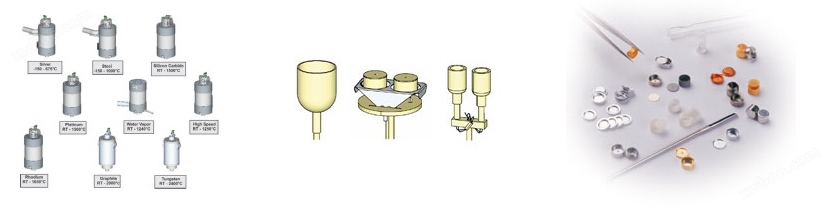

Wide selection of crucibles: NETZSCH offers various crucibles such as aluminum, silver, gold, copper, platinum, alumina, zirconia, graphite, stainless steel, etc., which can meet almost all material testing and applications.

The unique steam furnace option, equipped with a series of accessories for steam generation, gas mixing, and flow control, constitutes the perfect tool for studying the mass and energy changes inside the sample within the set absolute humidity and temperature range up to 1250 ° C.

If testing is required in a special atmosphere, STA 449 F1 Jupiter®Special anti-corrosion configurations can be provided. This configuration can be tested in corrosive or reducing atmospheres, with the gas flow control system placed in a separate box, the sample holder also specially configured, and the thermocouple in a protected state.

For very special samples or radioactive materials, STA 449 F1 Jupiter®It can be installed in glove boxes or hot chambers, with electronic components located away from the measuring unit, and all data cables and supporting equipment can be connected to one lead.

The newly launched high-speed furnace body is a great functional extension of existing STA and high-temperature DSC products. This type of furnace body does not need to be equipped with specialized instruments and can be installed together with other furnace bodies on the existing dual lifting devices of STA449Fx/DSC404Fx. If dual furnace bodies are not installed, an automatic sampler (ASC) can also be equipped for high-speed furnaces. The flexibility of this modular design, especially the high-speed furnace can be combined with ASC, which saves a lot of time and greatly shortens the sampling period.

For samples that are prone to oxidation at high temperatures, OTS can be equipped ™ The Oxygen Trap System attachment effectively reduces the possibility of sample oxidation by adsorbing and blowing impurity oxygen in the atmosphere.

Automatic Sample Injection System (ASC) can be used for batch routine testing. The instrument can work day and night, not only making full use of the instrument but also saving a lot of time. (For example, conducting calibration tests on weekends when there is no one present). The injection turntable can hold up to 20 samples and reference crucibles at a time, and work in a customized order. The testing atmosphere and cooling device control are both automatic. Individual test condition programming and macro calculations can be performed for each sample. An easy to understand operating interface can guide users to complete a series of test program edits, and during the experiment, they can also make changes to the running program by inserting new test programs into the already written program.

Wide selection of crucibles: NETZSCH offers various crucibles such as aluminum, silver, gold, copper, platinum, alumina, zirconia, graphite, stainless steel, etc., which can meet almost all material testing and applications.

The unique steam furnace option, equipped with a series of accessories for steam generation, gas mixing, and flow control, constitutes the perfect tool for studying the mass and energy changes inside the sample within the set absolute humidity and temperature range up to 1250 ° C.

If testing is required in a special atmosphere, STA 449 F1 Jupiter®Special anti-corrosion configurations can be provided. This configuration can be tested in corrosive or reducing atmospheres, with the gas flow control system placed in a separate box, the sample holder also specially configured, and the thermocouple in a protected state.

For very special samples or radioactive materials, STA 449 F1 Jupiter®It can be installed in glove boxes or hot chambers, with electronic components located away from the measuring unit, and all data cables and supporting equipment can be connected to one lead.

The newly launched high-speed furnace body is a great functional extension of existing STA and high-temperature DSC products. This type of furnace body does not need to be equipped with specialized instruments and can be installed together with other furnace bodies on the existing dual lifting devices of STA449Fx/DSC404Fx. If dual furnace bodies are not installed, an automatic sampler (ASC) can also be equipped for high-speed furnaces. The flexibility of this modular design, especially the high-speed furnace can be combined with ASC, which saves a lot of time and greatly shortens the sampling period.

For samples that are prone to oxidation at high temperatures, OTS can be equipped ™ The Oxygen Trap System attachment effectively reduces the possibility of sample oxidation by adsorbing and blowing impurity oxygen in the atmosphere.

Automatic Sample Injection System (ASC) can be used for batch routine testing. The instrument can work day and night, not only making full use of the instrument but also saving a lot of time. (For example, conducting calibration tests on weekends when there is no one present). The injection turntable can hold up to 20 samples and reference crucibles at a time, and work in a customized order. The testing atmosphere and cooling device control are both automatic. Individual test condition programming and macro calculations can be performed for each sample. An easy to understand operating interface can guide users to complete a series of test program edits, and during the experiment, they can also make changes to the running program by inserting new test programs into the already written program.

Online inquiry